Manufacturing

Flexibility

Gain greater flexibility over your product development process and mitigate risk throughout your project’s lifecycle.

Resource Optimization

Keep projects on schedule and costs down with consistent, reliable and streamlined SMT manufacturing processes.

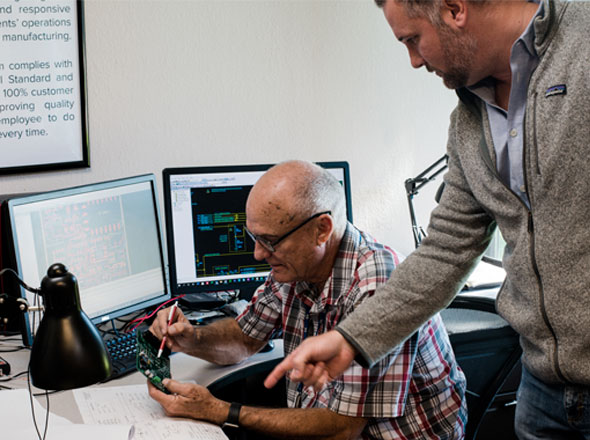

Full-Service Support

Work with a team of experienced engineers and industry professionals to ensure the quality and functionality of each circuit board design.

Cost-Effective BOM Parts Sourcing

We provide initial component sourcing for a project’s bill of materials (BOM), including all assemblies, sub-assemblies, raw materials, parts and other components. Throughout the souring process, we vet all materials for quality and keep an eye on scalability and accessibility. We can also produce durable parts and fixtures in house as needed.

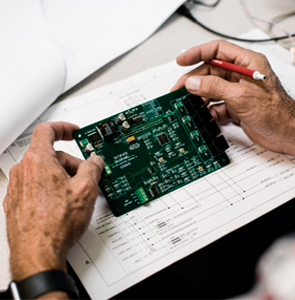

Board Design, Review + Functional Testing

During our comprehensive review of the design files, our engineers ensure there is no discrepancy between Gerber, BOM and netlist data to reduce the opportunity for costly failures or missteps in PCBA NPI. Assembly will also be reviewed for breakaways, fiducials and other processing features. Other areas of expertise include RF, Design for Manufacturability (DFM) enclosure design and FAI review. We also offer Federal Communication Commission (FCC) certification consulting.

Obsolescence/EOL Redesign

Our in-house engineers can remove End of Life (EOL) circuit board components or modules on low quantities of projects. We work closely with clients to help remove the burden and obstacles associated with obsolescence.

Industries We Serve

With a streamlined process and flexible electronics manufacturing services, from PCBA to full box builds, we serve leading companies in a wide range of industries.