Capabilities

SMT Component Sourcing

Drawing on extensive global partnerships, our in-house sourcing process allows us to provide high-quality, cost-effective material sourcing nationwide and overseas. Capabilities include:

- Seamless material sourcing and procurement

- 33+ years of global sourcing experience

- Established network of suppliers

- On-site quality control

- Parts reclamation

- Lot control and traceability

- Parts storage and lifetime buy

- Alternate sourcing and comparison

PCB Fabrication Process

Our streamlined PCB fabrication process benefits established international partnerships in the U.S. and China. Capabilities include:

- Full-service fabrication

- Build out services

- Established PCB fabrication vendor relationships

- International network

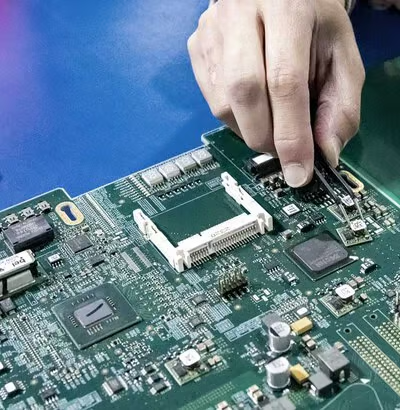

SMT Assembly

Our on-site turnkey PCB assembly services allow us to produce fully functional PCBAs, built, programmed and tested to customer specifications. Capabilities include:

- Cable harness and point-to-point wiring

- Sub-assembly

- Enclosure modification and assembly

- Final Unit Test (FUT)

- Dedicated box build area with integrated material holding and testing

- Burn in available to customer specification

- Configure and build to order

- Design for Manufacturability (DFM)

- Prototype and volume production

- New product introduction

- Chassis and box build

- Full system integration

- Design review

- Prototype, BOM and configuration control support

- Stencil design

- Integrated process development

- Full-service documentation

Printed Circuit Board Testing

By offering an extensive range of testing options, we work to ensure boards are fully functional and identify issues with non-functional or failed designs. Capabilities include:

- Functional testing

- FICT testing (TAKAYA Flying Probe Tester)

- Board and system-level testing

- RF performance to specification (frequency and power)

- Custom test fixture and software implementation

- Optical inspection

- Compliance testing and support

- Test fixtures and procedure

Repair

Combined with testing, our in-house PCB repair services allow us to assess, troubleshoot and problem solve for circuit board failure or obsolescence. Capabilities include:

- Field service return and repair

- End of Life (EOL)/obsolescence

- Failure Mode and Effects Analysis (FMEA)

- Custom board refurbishing