With the New Year hovering on the horizon, there’s no better time to take stock of your inventory. Are failed printed circuit boards taking up space on your shelf? Don’t let these boards, which are essentially “dead money” — an investment that’s not paying off — drag your prototyping or design process down.

There are several reasons that a PCB design may fail, ranging from wrong components to open solder joints in hidden connections and possible open traces in the PCB, yet pinpointing the specific cause can be costly and complicated, especially for small-batch builds. That’s why we are proud to announce the newest addition to our technology and a not-so-secret weapon that can save you time, money and headaches on board testing.

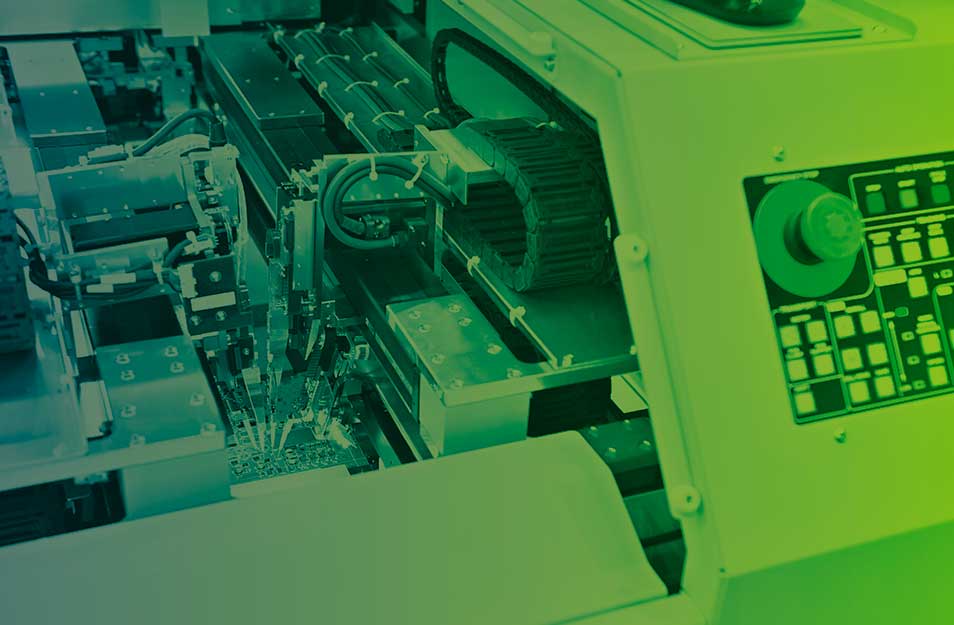

The TAKAYA Flying Probe Tester is ideal for low- to mid-volume builds, including prototypes and early-stage iterations. As a fixtureless in-circuit test (FICT) system, it offers greater flexibility when it comes to testing double-sided boards or other assemblies with hard-to-reach components than a standard bed-of-nails in-circuit testing (ICT) system which is more rigid and costly. Learn more about the benefits the Flying Probe Tester offers and how it can help you make the most of your PCB investment.

Cost Savings + Fast Turnaround

As mentioned above, bed-of-nails ICT often comes with a higher price tag and can take weeks to create the custom fixtures needed for each board test. On the other hand, there is no need to create unique fixtures with the TAKAYA Flying Probe Tester which helps keep costs down and means no time is lost when programming different iterations or designs.

Design Flexibility

In addition to saving time and money, the flying probe test can accommodate a wider range of board assemblies and designs. This is especially valuable for diverse or detailed boards that may run into accessibility issues with other testing options. For example, bed-of-nails ICT relies on fixed probes that must be able to reach each contact point from a stationary position, while flying probes are mobile and can access hard-to-reach design elements.

Precision + Reliability

The TAKAYA Flying Probe Tester is equipped with automatic optical testing that can identify missing, offset or polarity-reversed components. It also has an internal camera that scans and records component bar codes throughout the testing process and each of the flying probes can register contact points as small as 60 micrometers.

Versatile + Comprehensive Testing

The machine comes equipped with an expansive of testing options available, including analog and digital measuring equipment, four-quadrant power supplies, sine and rectangular wave generators, frequency counters, sensors and more. As a result, it has the versatility to test double-sided board designs and even detailed components such as LEDs.

Yet even with all this advanced technology, it is ultimately people that make the machine work. At Alert Tech SMT, we have extensive talent in-house to help move your project along quickly while giving you the benefit of those decades of experience. So, as you head into the New Year, don’t let your faulty boards hold you back. Backed by 30 years of experience, our team of in-house engineers will help you identify the root cause of the issues — and how to fix them. At Alert Tech SMT, we have the tools and the expertise to make sure you receive the PCB testing support you need. Send us your bad boards today and let’s solve your dead money problem.